What is Aluminum Bar?

Aluminum bar is a kind of bar shaped aluminum profile product which is produced from the raw material aluminum through a certain manufacturing process. Aluminum bars are widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

According to different processing technologies, aluminum bars can be divided into cast aluminum bars, forged aluminum bars, drawn aluminum bars and extruded aluminum bars.

According to the extrusion profile, aluminum bars can be divided into aluminum round bars, aluminum square bars, hexagonal aluminum bars and special-shaped aluminum bars.

According to the diameter, aluminum bars can be divided into ordinary aluminum bar and super large diameter aluminum bar.

Classification of Aluminum Bars by Processing Technology

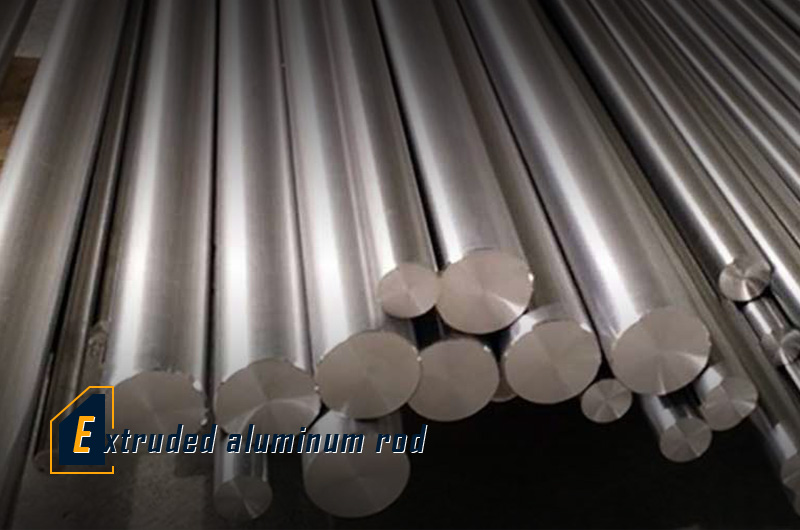

Extruded Aluminum Bar

Extrusion process is the most commonly used manufacturing process in aluminum bar processing. It is to form and extrude aluminum bars on metal materials at a certain temperature by the virtue of the good plasticity of raw materials.

Production process flow of extruded aluminum bar:

- Preparation before extrusion;

- Extrusion;

- Stretching and Straightening;

- Sawing finished products, trimming and framing.

Common alloy of extruded aluminum bar: 1050, 1060, 2011, 2014, 2017, 2024, 2618, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075.

Aluminum billets

The casting aluminum bar has the following production steps. First pure aluminum or aluminum alloy ingots are prepared according to the standard composition ratio, and then manually heated to become aluminum alloy liquid or molten state, and then poured into the aluminum bar mold cavity through the professional aluminum bar mold or the corresponding process, and finally cooled to form aluminum bars.

Production process of Aiboer Technology billets:

- Smelting

- Casting

- Sawdust

- Aluminum rod homogenization

- Refrigeration and rod washing

Forged aluminum bar

Aluminum forged bar is forged and formed by forging equipment, which requires a large amount of processing. However, the microstructure of forgings is relatively dense, and internal defects are not easy to occur. Therefore, aluminum forged bars are widely used for processing parts with high requirements, such as valve seats, valve cores, valve stems, etc.

Process flow of forged aluminum bar:

- blanking and heating

- Plastic deformation (continuous forging)

- subsequent processing

- quality inspection

- Packaging and delivery

Common alloy of forged aluminum bar: 2A01 2A02 2A10 2A11 2A12 3A21 3003 3004 3005 5A02 5A03 5A05 5B05 5A06 5050 5052 5056 5086 6A02 61016005 6063 6061 6082 7A04.

Temper: H112, T6, T652, T73, T735 etc.

Maximum diameter: 650mm

Application:

Aluminum forged bars are used in various industries, including aircraft, aerospace, automobile, construction, electrical appliances, military and national defense, marine, petrochemical and process equipment industries.

High strength weight ratio: for fuselage, car frame and panel, wheels.

Corrosion resistance: for fasteners, structural components and frames for building and decorative building elements, processing equipment and marine equipment.

Wear resistance and durability: for process equipment, fasteners and some motor parts.

Forging: generally refers to the solid deformation of metal materials under high temperature to reach the product shape.

Casting: after the metal material is melted, the liquid is poured into the mold cavity to reach the product shape;

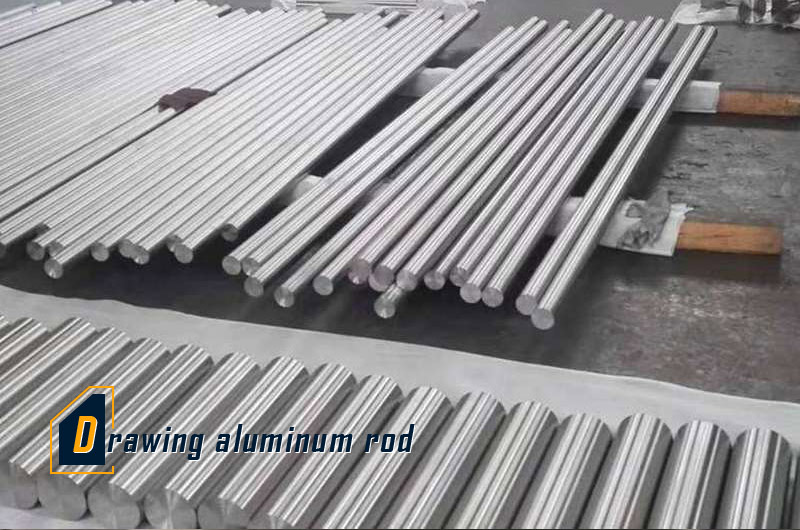

Drawing (fine drawing) aluminum bar

Under the action of tensile force, the metal plastic forming method of aluminum alloy billets to obtain products with the same size and shape as the die hole by gradually reducing the cross-sectional area of the drawing die hole is called stretching. Drawing is widely used in the production of tubes, rods, shapes and wires. The drawing process of aluminum and aluminum alloy products is generally carried out at room temperature, so it is often called cold drawing.

Features of fine drawn aluminum bar:

- Precise size and smooth surface.

- Simple operation.

- The strength of aluminum bar can be improved due to cold work hardening.

- Fast stretching speed and high efficiency.

Classification according to the shape of aluminum bar

Round aluminum bar aluminum bars with circular cross section are called round aluminum bars. The common round aluminum bar is generally obtained by extrusion. Round aluminum bar is the most widely used aluminum bar. We can further process the aluminum bar according to customer needs, such as sawing, polishing, etc.

| Alloy | 2011, 2014, 2017, 2024, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075 |

| Diameter (mm) | 3-350 |

| Length (mm) | 1000-6000 (also can cut to size) |

Flat/Rectangular bar the cross section of rectangular aluminum bar is rectangular. It is an extruded aluminum bar with a 90 degree acute angle. Aiboer has a huge inventory of rectangular aluminum bars, which can quickly complete the preparation and shipment. The rectangular aluminum bar is processed to a certain extent and often used in the power industry.

Rectangular aluminum bar extrusion is also called aluminum flat bar, aluminum busbar, aluminum rectangle bar

| Alloy | 2011, 2014, 2017, 2024, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075 |

| Thickness (mm) | 1-160 |

| Width (mm) | 6-570 |

| Length (mm) | 1000-6000 (also can cut to size) |

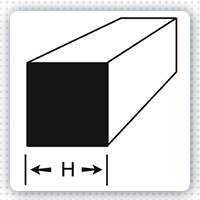

Square aluminum bar the cross section of aluminum square bar is square, and has the advantage of light weight, high stability, corrosion resistance, easy cutting, drilling or milling. Aluminum square bar is usually made by extrusion and is widely used in various buildings, manufacturing, parts processing and other industries.

| Alloy | 2011, 2014, 2017, 2024, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075 |

| Common dimensions (mm) | 6-160 |

| length (mm) | 1000-6000(also can cut to size) |

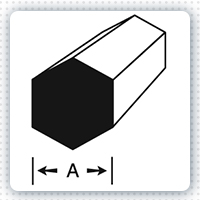

Hexagonal aluminum bar hexagonal aluminum bars are commonly referred to as "hex bars". Typical applications include the production of various fasteners, including nuts, bolts and fasteners. Aiboer Technology's hexagonal bars are available in a variety of sizes and alloy grades.

| Alloy | 2011, 2014, 2017, 2024, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075 |

| Width (mm) | 6-80 |

| Length (mm) | 1000-6000 (also can cut to size) |

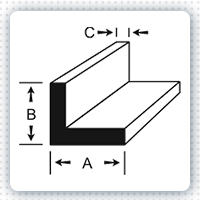

Angue barangle aluminum, also known as L-shaped aluminum, is an aluminum profile with two sides perpendicular to each other. The two sides of angle aluminum can be equal or unequal. Angle aluminum is also a general aluminum profile, which is mainly used in construction, decoration, industry and other fields.

| Alloy | 2011, 2014, 2017, 2024, 5052, 5083, 5086, 5454, 5754, 6061, 6063, 6082, 7003, 7022, 7050, 7055, 7075 |

| Side length (mm) | 10-280 |

| Thickness (mm) | 0.5-10 |

| Length (mm) | 1000-6000 (also can cut to size) |

Typical alloy for Aiboer Technology bar

1000 aluminum bar

1050 aluminum bar

Feature: the aluminum content is above 99.5%. It has the advantages of high plasticity, corrosion resistance, good conductivity and thermal conductivity. However, the strength is low and the machinability is poor without heat treatment. Contact welding and gas welding are acceptable.

Application: it can be used in reflective plate, decoration, chemical industrial container, etc.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 1050 | round | diameter: 3-350 | O, H112 | N |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagonal | width: 6-80 | N | ||

| angular |

Side length: 10-280 thickness: 0.5-10 |

N |

1060 aluminum bar

Features: 1060 aluminum alloy bar, with aluminum content of more than 99.6%. It has good elongation and tensile strength, can fully meet the conventional processing requirements (stamping, stretching), and has high formability.

At the same time, 1060 aluminum bar also has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. However, the strength is low, the heat treatment cannot be strengthened, and the machinability is poor. It can be used for gas welding, hydrogen atom welding and contact welding, and is not easy to braze. Easy to bear all kinds of pressure processing and stretching, bending.

Application: it is widely used in products with low strength requirements, such as conductive media, electronic parts, chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces and plates, nameplates, etc.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 1060 | round | diameter: 3-350 | O, H112 |

8, 10, 12, 13, 14, 15, 16, 18, 20, 22, 25, 28, 30, 32, 35, 38, 40, 45 , 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100 |

| square | Side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

2000 aluminum bar

2A12 aluminum bar

Feature: it is a kind of high strength duralumin and can be strengthened by heat treatment. 2A12 aluminum alloy has good spot welding performance, and there is a tendency to form intergranular cracks when gas welding and argon arc welding are used. 2A12 aluminum alloy has good machinability after cold work hardening.

Application: it is applied to the occasions requiring high strength and hardness (including high temperature). Heavy forgings, thick plates and extruded materials are used for aircraft structural parts, multi-stage rocket first stage fuel tank and spacecraft parts, wheel, truck frame and suspension system parts.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 2A12 | round | diameter: 3-350 | T3, T351, T4, T451, T6, T651, T6511, T7351 | 5-560 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

2A14 aluminum bar

Feature: it can be used as 2A50 alloy to make forged aluminum bars. The difference between 2A14 and 2A50 is that it has high copper content, so it has high strength and good thermal strength. But the plasticity in hot state is not as good as 2A50. The alloy has good machinability, resistivity, good resistance to spot welding and seam welding, and poor resistance to electric arc welding and gas welding.

Application: 2A14 is widely used in free forging and die forging with complex shape.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 2A14 | round | diameter: 3-350 | T3, T351, T4, T451, T6, T651, T6511, T7351 | 20, 30, 35, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 100, 110, 120, 130, 140, 150 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

2014 aluminum bar

Feature: 2014 aluminum alloy bar belongs to duralumin alloy and can be used for forging aluminum bar. Compared with 2A50, it has higher strength and better thermal strength, but its plasticity in hot state is not as good as 2A50. 2014 aluminum bar has good machinability, good contact welding, spot welding and roll welding performance, and poor electric arc welding and gas welding performance. It can be strengthened by heat treatment and has extrusion effect.

Application: It is applied to the occasions requiring high strength and hardness (including high temperature), such as aircraft heavy, forging, thick plate and extrusion materials, wheels and structural elements, multi-stage rocket first stage fuel tank and spacecraft parts, truck frame and suspension system parts.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 2014 | round | diameter: 3-350 | T3, T351, T4, T451, T6, T651, T6511, T7351 |

20, 30, 35, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 100, 110, 120, 130, 140, 150 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

5000 aluminum bar

5052 aluminum bar

Feature: the main alloy element of 5052 aluminum bar is magnesium, which has good formability, corrosion resistance, weldability and medium strength. It is the most widely used anti rust aluminum bar.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 5052 | round | diameter: 3-350 | O F H12 H14 H22 H24 H32 H34 H38 H111 H112 |

5, 6, 8, 10, 12, 13, 14, 15, 16, 18, 20, 22, 30, 32, 35, 38, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 120, 150, 160, 170, 180, 200 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

5083 aluminum bar

Feature: rust prevention, corrosion resistance, high molding, fatigue resistance, can not be strengthened by heat treatment.

Application: it is mainly used for low load parts that require high plasticity and good weldability and work in liquid or gas medium.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 5083 | round | diameter: 3-350 | T3, T351, T4, T451, T6, T651, T6511, T7351 |

14, 15, 16, 18, 20, 22, 25, 28, 35, 38, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 120, 130, 140, 150, 160, 190, 200 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

5A02 aluminum bar

Feature: rust prevention, can not be strengthened by heat treatment, has high plasticity, good shape and low strength, but is stronger than 3A21 alloy

Application: 5A02 aluminum alloy is suitable for welding structures and containers with high process plasticity requirements and good corrosion resistance, such as fuel tanks, gasoline and lubricating oil pipes, nails, flanges, light load parts, interior trim parts of ships and vehicles, wire rods, and used as rivets or welding rods.

6000 aluminum bar

6061 aluminum bar

Features: medium strength, excellent processability, good corrosion resistance, excellent welding characteristics, high electroplating and toughness, no deformation after processing, dense and defect free materials, easy polishing, easy coloring film, excellent oxidation effect, etc.

Application: it is widely used in various industrial structural parts requiring certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, railway vehicles, furniture, etc.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 6061 | round | diameter: 3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-560 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

6063 aluminum bar

Feature: it has excellent processability, corrosion resistance, excellent weldability and excellent anodizing effect. Its disadvantage is that after quenching, if it is left at room temperature for a period of time, it will have a negative impact on the strength in aging (parking effect).

Application: it is widely used in building profiles, irrigation pipes, pipes, rods and profiles for vehicles, stands, furniture, elevators, fences, etc.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 6063 | round | diameter: 3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-200 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

6082 aluminum bar

Feature: it is a heat treatable alloy with good formability, weldability, machinability, corrosion resistance and medium strength. 6082 aluminum bar has similar mechanical properties to 6061 aluminum bar. 6082 T6 aluminum bar has high mechanical properties.

Application: it is mainly used in mechanical structures such as automobiles and ships.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 6082 | round | diameter: 3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 8-270 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

7000 aluminum bar

7050 aluminum bar

Feature: super high strength, yield strength is close to tensile strength. The yield ratio is high and the strength ratio is also high, but the plasticity and high temperature strength are low. It is better to be a load-bearing structure used at room temperature and below 120℃. The alloy is easy to process, has good corrosion resistance and high toughness.

Application: 7050 aluminum bar is widely used in aviation and aerospace fields and has become one of the most important structural materials in this field.

Specification parameters and inventory

| Alloy | Shape | Size(mm) | Temper | Inventory Unit (mm) |

| 7075 | round | diameter: 3-560 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-560 |

| square | side length: 6-160 | N | ||

| rectangle |

thickness: 1-160 width: 6-570 |

N | ||

| hexagon | width: 6-80 | N | ||

| angular |

side length: 10-280 thickness: 0.5-10 |

N |

7075 aluminum bar

Feature: it belongs to A-Zn-Mg-Cu super hard aluminum. It is a kind of cold treated forging alloy with high strength, far superior to mild steel. 7075 aluminum alloy has tight structure and strong corrosion resistance.

Application: aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf ball head, shoe mold, fixture, mechanical equipment, etc.

Why choose us?

Aiboer is a large-scale modern aluminum processing enterprise integrating scientific research, processing and manufacturing. It has 12500 tons of horizontal extruders, 2800 mm hot rolling mills and cold rolling mills, and 6000 tons of stretching straighteners. It has the first "1+4" hot continuous rolling production line with world advanced level.

In addition, Aiboer has many imported cutting machines, full-automatic feeding sawing machines, vertical large automatic feeding machines and other processing equipment, which can process materials according to the needs of enterprises in various industries to meet different processing needs. We also provide services of aluminum rod flaw detection, sawing, milling, etc.

Professional services

Sawing, milling face, film laser engraving, bending

Testing Equipment

Production equipment