Aluminum wires, aluminum coil strips, aluminum tubular bus bar, aluminum flat bus bar, CCA etc., have been widely used in the field of electric power, such as cables, electrical motors, electrolytic capacitors, transformers, radiators, etc.

The high structural strength, light weight, good electrical conductivity, high ductility, and non-magnetic properties of aluminum make aluminum and its alloys indispensable materials for the power industry. Main application areas include cables, bus bars, overhead transmission lines, motors, foil windings, electrolytic capacitors, transformers, heat sinks and more.

Application of aluminum wire in power field

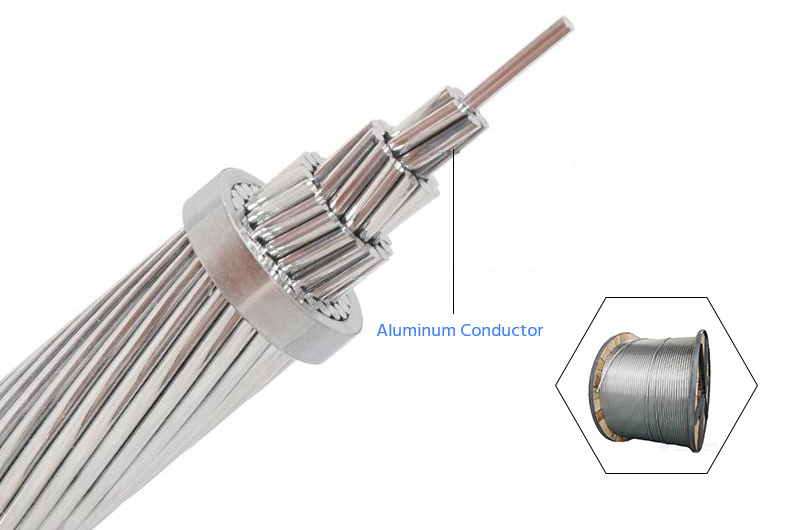

Aluminum conductor

AAC/All aluminum conductor

AAC is a concentric-lay-stranded conductor consisting of aluminum alloy 1350-H19 wires available in both single-layer and multi-layer constructions.

This all aluminum conductor is a kind of aluminum product made through stranding aluminum wires. It is used for the electricity distribution lines with short span length and small load-carrying capability of the pole.

The AAC provides reliable performance for overhead power transmission and distribution lines. This standard covers hard drawn round aluminum wires for electrical purposes, which are used as hard drawn stranded aluminum cables and aluminum conductor steel reinforced composite wires.

Standard:

ASTM B 231, BS 215 Part 1, IEC 61089, DIN 48201, CSA C 49, JIS C 3109, etc.

ACSR/Aluminum conductor steel reinforced

ACSR is a concentric-lay-stranded conductor consisting of a single core wire or a stranded steel central core with one or more layers of 1350 H19 stranded aluminum wires. The steel core wires are protected from corrosion by galvanizing, aluminum-clad alloy or zinc-5% aluminum mischmetal alloy coating. Standard, high, extra and ultra high strength steel is also available.

Standard:

ASTM B 232, BS 215 Part 2, IEC 61089, DIN 48204, etc.

High-strength AAAC

6101 6201 aluminum alloy conductors are concentric-lay-stranded, similar in construction and appearance to 1350 grade aluminum conductors. They were developed to meet the needs of overhead applications for economic conductors. This application requires higher strength than grade 1350 aluminum conductors, but no steel core. DC resistance at 20°C of the 6201, 6101 conductors and of the standard ACSR of the same diameter are approximately the same. Overhead transmission conductors of the 6201, 6101 alloys are harder and, therefore, have a greater resistance to abrasion than conductors of 1350-H19 grade aluminum.

Aluminum magnet wire

Aluminum magnet wire is an insulated wire used to manufacture coils or windings in electrical products. Magnet wire is usually divided into enameled aluminum wire, wrapped aluminum wire, enameled wrapped aluminum wire and inorganic insulated aluminum wire.

| Aluminum wire | Aluminum flat wire | Aluminum round wire |

| Size | A: 1-10mm B: 3-30mm | Diameter: 0.15mm-6.00mm |

| CLass | 180 , 200, 220 | 130, 180, 200, 220 |

| Standard | IEC, NEMA, GB, JIS | IEC, NEMA, GB, JIS |

| Package | 40KGS-60 KGS | 40KGS-60 KGS |

The use of aluminum magnet wire can be divided into two types:

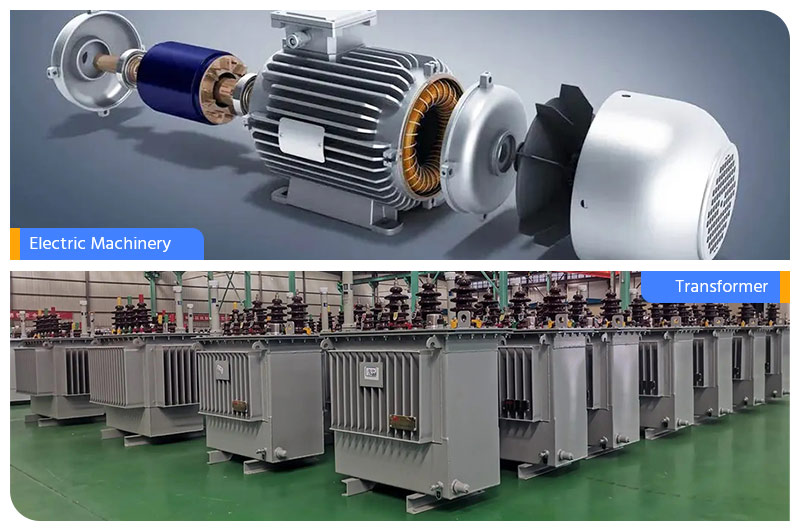

General purpose, mainly used in motors, electrical appliances, instruments, transformers, etc., to generate electromagnetic effects by winding coils, and use the principle of electromagnetic induction to achieve the purpose of converting electrical energy and magnetic energy.

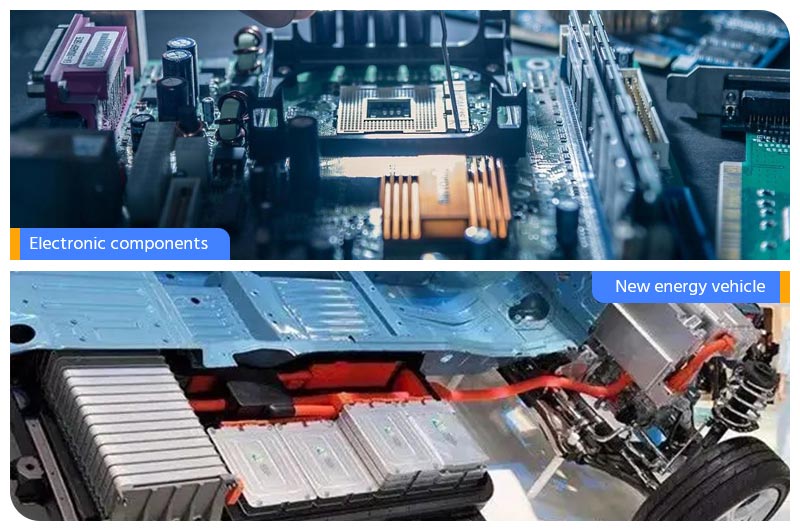

Special purpose, used in electronic components, new energy vehicles and other fields with special characteristics requirements, such as fine electronic wires are mainly used for the transmission of information in the electronics and information industries, and special wires for new energy vehicles are mainly used in the production of new energy vehicles manufacture.

Electrical aluminum flat wire is a wire that is continuously extruded from an oil-free electrical round aluminum rod through a mold of a certain specification. The electrical aluminum flat wire produced by extrusion has a smooth conductor surface, no burrs, uniform size and tensile strength, and low resistivity. It can be used as a finished product or an intermediate product, which is widely used in the windings of motors, transformers, electric welding machines and other similar electrical equipment.

Enamelled flat aluminum wireEnamelled flat aluminum wire includes 180 grade polyesterimide enameled flat aluminum wire, 200 grade polyamideimide enameled flat aluminum wire, and 220 grade polyamide enameled flat aluminum wire.

NOMEX paper-wrapped flat aluminum wireThis kind of aluminum wire is a wire extruded from an electrician round aluminum rod through a mold of a certain specification, and then wrapped by T410 NOMEX insulating paper. It is mainly used for transformers, electric welding machines, electromagnets or other Similar to the winding of electrical equipment products.

Glass fiber wrapped aluminum flat wireGlass fiber wrapped aluminum flat wire has three grades of 130, 155, and 180, and the insulation thickness generally has four grades of 20, 30, 40, and 50. This product is widely used in the winding of transformers, electromagnets, electric welding machines or other similar electrical equipment products. The electrical bare aluminum wire produced by the extrusion process is the most ideal material for the production of glass fiber clad aluminum wire.

Application of aluminum profiles in the field of electric power

Conductive aluminum tube

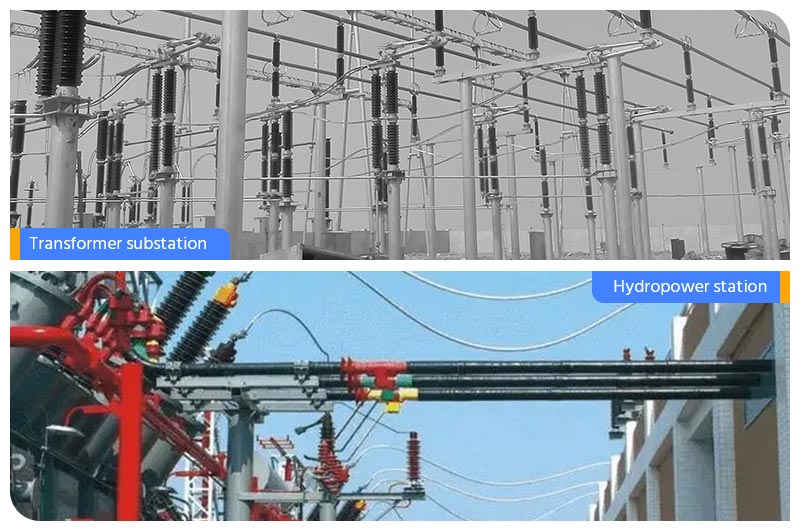

Conductive aluminum alloy tubes are mainly used as conductor connections between power grid transmission wires and substation transformers in power construction projects, jumpers in transmission lines, connecting conductors in power equipment, and overcurrent conductors in high-current DC ice melting devices.

It is a new conductor that replaces the traditional rectangular, slotted, rod-shaped busbars and flexible conductors. It is one of the key equipment (materials) in the power transmission and transformation system. It plays a crucial role in the safe and reliable operation of the power transmission and transformation system and power equipment.

Aiboer Technology tubular bus bar size:

| Aluminum alloy | Temper | Out of diameter | Wall thickness | Length |

| Alloy 6063 | T7, T6 | 50mm-450mm | 3mm- 15mm | MAX 15 meters |

| Alloy 6101 | T7, T6 | 50mm-450mm | 3mm- 15mm | MAX 15 meters |

| Alloy 6101B | T7, T6 | 50mm-450mm | 3mm- 15mm | MAX 15 meters |

| Alloy 6063G | T7, T6 | 50mm-450mm | 3mm- 15mm | MAX 15 meters |

Aluminum tubular bus bar: A tubular bus bar mainly using aluminum or aluminum alloy as conductor. The conductivity of aluminum is second only to silver, copper and gold. Although its conductivity is only 2/3 of copper, its density is only 1/1 of copper. Therefore, in order to realize the transmission of the same amount of electricity, the aluminum tubular bus bar often needs to be enlarged and thickened.

In addition, the oxide film on the aluminum surface not only has the ability to resist corrosion, but also has a certain degree of insulation. In addition, the price of aluminum tubular busbar is cheap. For engineering projects with cost requirements, aluminum tubular busbar is still quite widely used in power construction.

Conductive aluminum busbar

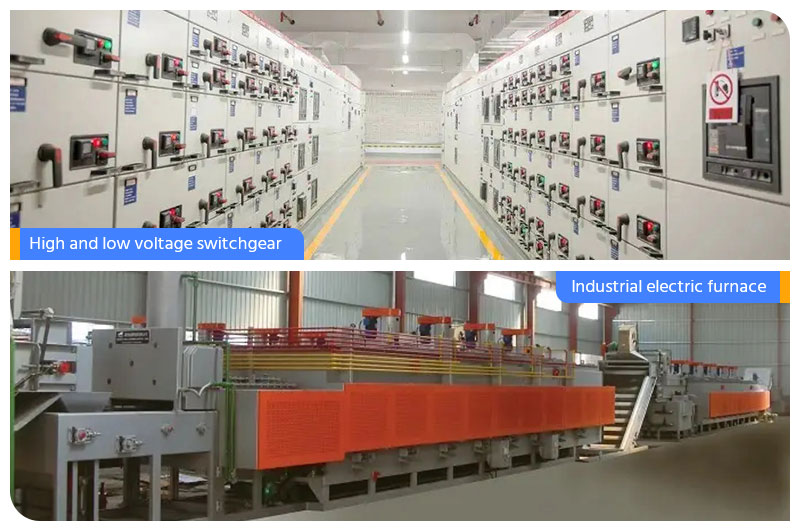

The function of aluminum busbar is to transmit electrical energy. It is a product with the ability to collect and distribute electrical energy. Aluminum busbar, also known as busbar or current-carrying bar, is a conductor that carries current, mainly used for switchgear and control convergence, distribution and transmission of power in equipment to connect primary equipment.

It is widely used in transformer installation, high and low voltage switch cabinets, vacuum electrical appliances, closed busbars, generators and busbars, rectifier equipment, rectifier cabinets and isolation switches, automobiles, electric locomotives, industrial furnaces, mining explosion-proof electrical appliances, generator sets, carbon Soft connection of brush wire and connection between busbars.

Aiboer Technology flat bus bar size:

| Aluminum alloy | Temper | Thickness | Width | Length |

| Alloy 6063 | O, T6, T61, T63, T64, T65, T7 | 2-20mm | 10mm- 300mm | 3000mm-6000mm |

| Alloy 6101 | O, T6, T61, T63, T64, T65, T7 | 2-20mm | 10mm- 300mm | 3000mm-6000mm |

| Alloy 1350 | O, T6, T61, T63, T64, T65, T7 | 2-20mm | 10mm- 300mm | 3000mm-6000mm |

| Alloy 1050 | O, T6, T61, T63, T64, T65, T7 | 2-20mm | 10mm- 300mm | 3000mm-6000mm |

| Alloy 1060 | O, T6, T61, T63, T64, T65, T7 | 2-20mm | 10mm- 300mm | 3000mm-6000mm |

Enclosed aluminum bus bar

It can be divided into dense insulated bus bar and air insulated busbar line, suitable for three-phase four-wire system or three-phase five-wire system, rated working voltage 60v, Q rated working current 250~2600, frequency 50H.

It has the advantage of exposed structure , high dielectric strength, large transmission current, good interchangeability, accurate electrical performance, easy to use and so on. It also has a series of other characteristics such as easy installation and maintenance, long service life and so on. Widely used in industrial and mining enterprises, high-rise buildings and public facilities.

Non-enclosed aluminum busbar

It is referred to as aluminum busbar, which refers to the connection of voltage distribution devices at all levels in substations.

Application of aluminum coil and strip in the field of electric power

The aluminum strip and foil for dry-type transformers are made of high-quality pure aluminum, which has the characteristics of high conductivity, soft quality, smooth surface and no burrs. The requirements for many technical indicators such as electrical conductivity, burr curling, side bending and surface quality of aluminum strips and foils are very high.

Aiboer Technology coil strip:

| Aluminum alloy | Temper | Thickness | Width | Inner Diameter |

| Alloy 1070 | O | 0.2mm ~ 3mm | 100mm ~ 1000mm | 300mm ~ 510mm |

| Alloy 1350 | O | 0.2mm ~ 3mm | 100mm ~ 1000mm | 300mm ~ 510mm |

| Alloy 1050 | O | 0.2mm ~ 3mm | 100mm ~ 1000mm | 300mm ~ 510mm |

| Alloy 1060 | O | 0.2mm ~ 3mm | 100mm ~ 1000mm | 300mm ~ 510mm |

Transformer aluminum-aluminum strip mainly used in large transformers, solar energy, power industry.

Application of clad metal in power field

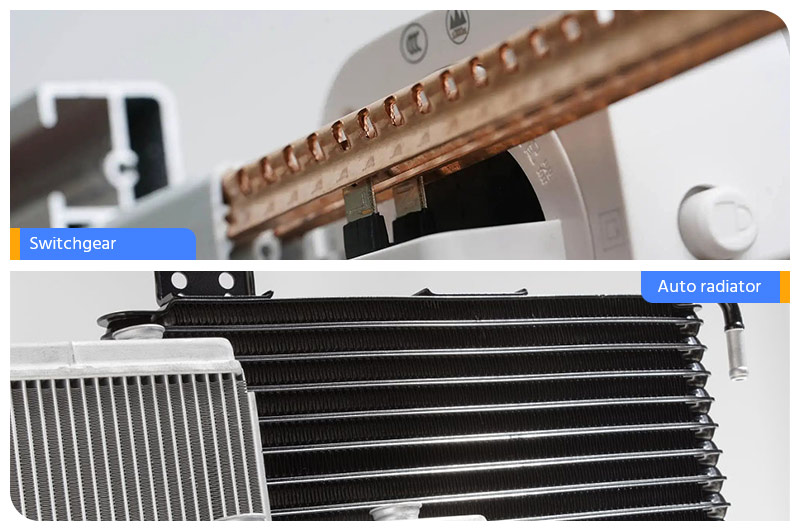

Copper-aluminum gaskets are mainly used in contact gaskets, conductive connection boards, various high and low voltage power distribution devices, etc.

The surface of the copper-aluminum composite busbar is copper, so the oxidation resistance is the same as that of copper. The mutual lap is the lap of copper and copper, and its electrical life is the same as that of copper busbar when it is energized for a long time. After special process treatment, the creep deformation is small, and the performance is close to that of copper, which overcomes the fatal weakness of aluminum busbar, and has the same reliability as copper busbar.

Aiboer Theoretical Table of CCA

| Size | Thickness/mm | Width /mm | Length /mm |

| 20*4 | 4 | 20 | 1000 |

| 25*4 | 4 | 25 | 1000 |

| 30*4 | 4 | 30 | 1000 |

| 30*5 | 5 | 30 | 1000 |

| 30*6 | 6 | 30 | 1000 |

| 30*8 | 8 | 30 | 1000 |

| 30*10 | 10 | 30 | 1000 |

| 40*4 | 4 | 40 | 1000 |

| 40*5 | 5 | 40 | 1000 |

| 40*6 | 6 | 40 | 1000 |

| 40*8 | 8 | 40 | 1000 |

| 40*10 | 10 | 40 | 1000 |

| 50*5 | 5 | 50 | 1000 |

| 50*6 | 6 | 50 | 1000 |

| 50*8 | 8 | 50 | 1000 |

| 50*10 | 10 | 50 | 1000 |

| 60*5 | 5 | 60 | 1000 |

| 60*6 | 6 | 60 | 1000 |

| 60*8 | 8 | 60 | 1000 |

| 60*10 | 10 | 60 | 1000 |

| 80*6 | 6 | 80 | 1000 |

| 80*8 | 8 | 80 | 1000 |

| 80*10 | 10 | 80 | 1000 |

| 100*6 | 6 | 100 | 1000 |

| 100*8 | 8 | 100 | 1000 |

| 100*10 | 10 | 100 | 1000 |

| 120*8 | 8 | 120 | 1000 |

| 120*10 | 10 | 120 | 1000 |

Copper-aluminum composite board is a high-tech energy-saving conductor material, which has the characteristics of copper conductivity and low density of aluminum.

According to the characteristics of copper and aluminum, a specific process is used to make the interfaces of copper and aluminum fuse or diffuse with each other to form a close metallurgical bond, so that a bimetallic metallurgical bond between atoms is formed between them, with a bright and round surface, complete and defect-free.

It is a new material that combines the high-quality and stable electrical conductivity of copper with the low-cost energy of aluminum and low contact resistance.

Application fields of copper-aluminum transition plate include electric power, metallurgy, automobile, new energy, electrical equipment accessories, conductive track switchgear, cooler, automobile radiator, transformer, etc.

Aiboer has a high-standard metal material R&D and testing center, which can provide good products and services to the world. We have passed ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system certification. Our products have passed the Rohs environmental protection certification of the international SGS authoritative certification agency, and have passed the global supplier qualification certification of international electrical giants ABB and Schneider.